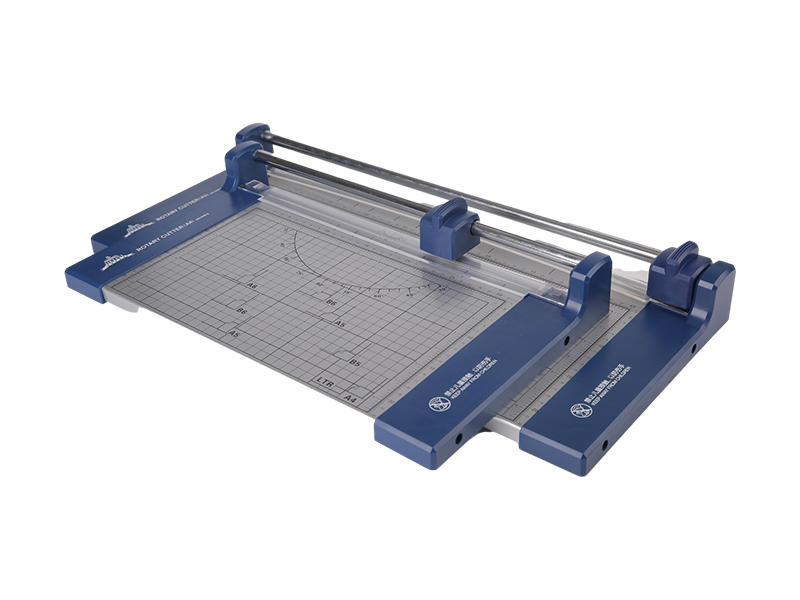

Sheet paper cutter

Sheet paper cutter is a kind of cutting machine with a wide range of applications and can be used to cut paper, leather, plastic, cardboard and other materials. The paper cutter is mainly composed of a main machine (also known as a gantry), a workbench, a paper pushing mechanism, a paper pressing mechanism, and a cutting mechanism. The paper pushing mechanism is used to push the paper to position and make post-rules, while the paper pressing mechanism compresses the paper in position to ensure that the original positioning accuracy is not damaged during the cutting process. The cutting mechanism is used to cut the paper, and the side baffle is used as Side block gauge, the workbench plays a supporting role.

In printing, packaging, book binding, etc., the cutting of the finished product from opening to printing and the cutting of the finished material after binding requires a paper cutter to cut, so the paper cutter is an important equipment for post-press processing. Sheet paper cutters are widely used in printing plants, binding plants, packaging plants, paper products processing plants, etc.

Cutting process of sheet paper cutter

1) Determine the position of the paper pusher according to the size of the paper to be cut

2) Make the paper that has been flushed close to the front surface of the paper pusher and the side fence to position the paper

3) The presser first descends to compress the paper, and then the cutter descends to cut the paper

4) After cutting, the cutter leaves the paper stack and returns, and then the paper press rises to reset.

.jpg?imageView2/2/format/jp2)